Image: Philip C. Lowe, FineWoodworking.com

Working title of project: A Modern Application of Traditional Japanese Joinery

CAN SOMETHING SO REFINED AND SPECIALIZED AS JAPANESE JOINERY FIND A NEW NICHE IN A MODERN PREFABRICATION OR MULTIPURPOSE CONTEXT?

Theoretical Justification: What is the purpose of this inquiry?

At this point, we understand Japanese joinery to be an artform. One which dates back over a thousand years, with a rich history of development and refinement which was closely linked to the social and economic context of Japanese society. Throughout hundreds of years of refinement, some of these joinery methods became so sophisticated and so niche that a specific joint may only exist in exactly one position, on one type of building. The tectonic qualities of Japanese joinery emerged organically and evolutionarily, as increasing structural complexity required more of these connections. Can such specific tectonic qualities be utilized in modern constructions as well?

The exigence of this Capstone is to find and explore a modern application for such highly specialized joinery beyond their traditional context; in a modern context where there is a potential application for Japanese joinery methods in prefabricated and/or multipurpose structural elements. It is in this change of context that this inquiry truly lives, as it will be researched whether or not Japanese joinery continues to lend itself well for construction in such a change of context.

Method: How I will study Japanese Joinery

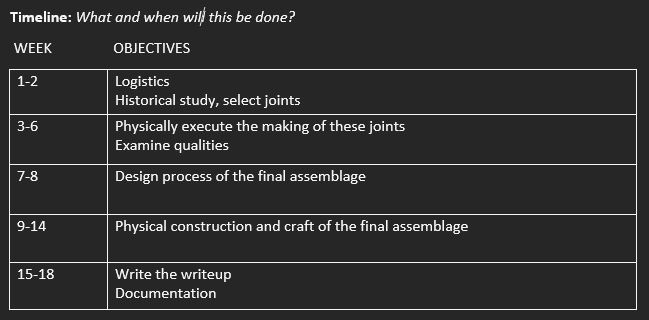

This inquiry into Japanese joinery begins with practical research of the joint typologies and their respective applications. This would involve a look at their qualities and use in a purely historical context. At this point, I can select five or so of the fundamental joinery methods to examine in greater detail for the purposes of this inquiry. Next, I will engage in a more personal, physical approach. I will make the joints out of real wood using only the tools available to the historic Japanese craftsman, and in doing so, gain a much deeper appreciation and insight into their qualities and application. I will not only understand the geometry and history of these joints, but the process, just as the traditional craftsman would have. After being informed through this pragmatic, historical research and the personal, hand craftsman’s experience, I will be equipped with the knowledge and ability to proceed.

Five or so of the more fundamental joinery methods have now been chosen based on their tectonic qualities. I now understand and have executed the process for their manufacture and function. Now, I will have a taxonomy of joint typologies and applications to be assessed in a kind of matrix. These five joints may be taken out of their typical application of compression, tension, torsion, or twisting in order to identify potentially unexpected relationships, from which I can draw upon for the final assemblage.

The final step is this final assemblage. Its form is entirely determined by the findings of this taxonomy of joint types, and as such I cannot speak to exactly how it will turn out at this stage. The goal would be to create a furniture piece of some sort, perhaps a stool, table, or chair, that can be disassembled and reassembled into multiple other forms because of its usage of Japanese joinery. Its parts could be standardized and replaceable. The legs and seats of multiple stools could be disassembled and reassembled to form a long bench, or a table and chair set, for example. This would be possible due to the tectonic nature of the joints as used throughout the assemblage, which would not be possible with modern standard fasteners like screws, or glued joints.

Logistics: Why I have chosen this scale

It is infeasible to attempt a physical construction as called for by this inquiry on the scale of an entire building, but the scale of a furniture piece is fitting for a project of this ambition. Even though Japanese joinery evolved as an architectural necessity, the final assemblage will likely be a furniture piece of some sort, or at least, on the scale of one. Even in the scale of furniture, the applications for Japanese joinery are well understood and highly specific. While initially invented for the most practical of structural purposes, many Japanese joinery techniques have found their way into the furnituremaker’s arsenal, as their structural potential and desirable aesthetic qualities free from unsightly fasteners have made them a go to for high-end woodworkers.

Where many furniture designs must go out of their way to hide fasteners, or settle for a permanent glue bond, Japanese joinery creates the opportunity for a celebration of the joint and the proud expression of its tectonic nature and craft. As such, it is understood to be a finer method of assembly in furniture as in architecture. this scale serves as a fitting and practical medium for my findings. This scale and the final product as a whole are not the drivers of this study, they are simply a practical means of validating my assertions.

Leave a comment